After several winter storms, most snow blowers still start and run. That doesn’t mean they’re in good shape. January is often when early wear turns into real problems. If you’re noticing snow blower problems after winter storms, the damage likely began weeks earlier.

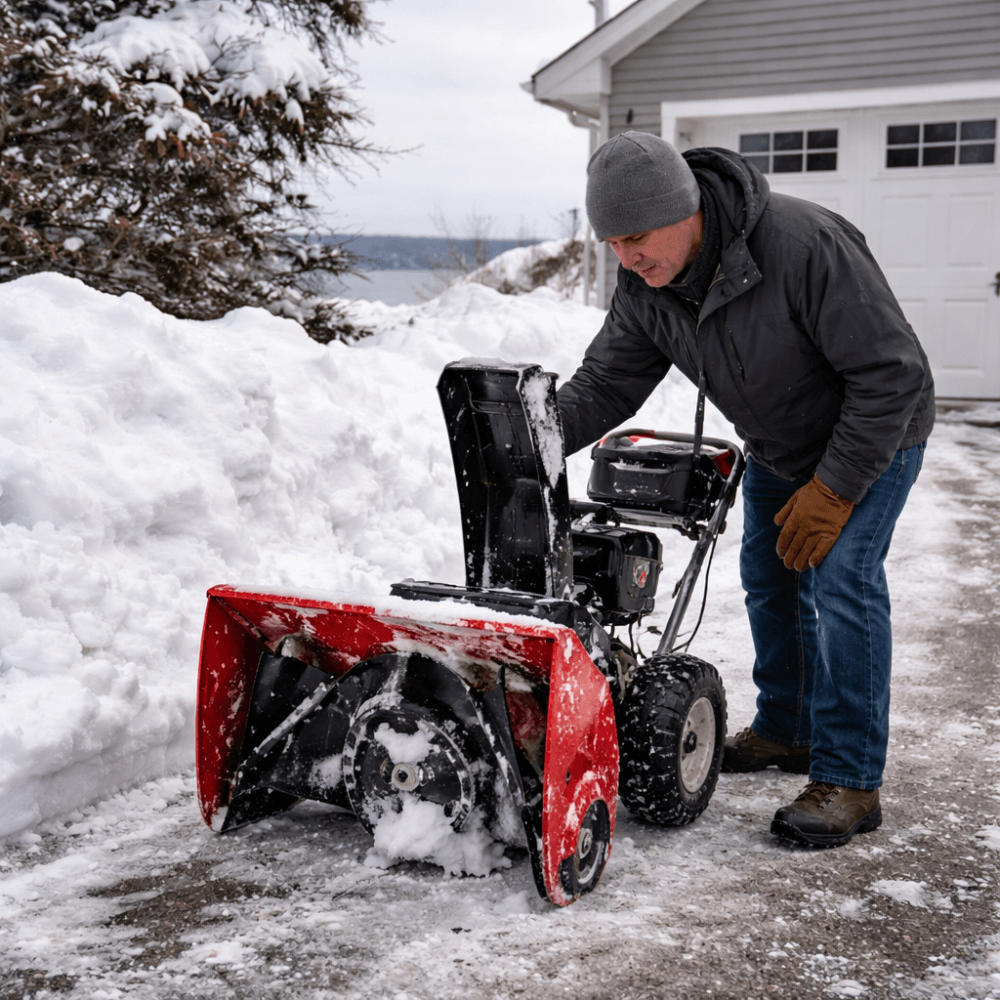

Along the New Hampshire Seacoast, snow equipment deals with wet, heavy snowfall, salt exposure, and constant freeze-thaw cycles. These conditions accelerate belt wear, freeze chute controls, and stress auger components. A short post-holiday equipment check can uncover issues early, before the next storm forces an emergency repair.

This guide walks through what to inspect, which warning signs matter most, and when professional snow blower service in New Hampshire makes sense.

Why Snow Blowers Fail After Repeated Winter Storms

Snow blowers rarely fail without warning. Most breakdowns build slowly over multiple storms.

Wet snow increases resistance on augers and belts. Plow berms hide ice chunks and debris that can bend components. Salt and moisture settle into fasteners, cables, and chute mechanisms, encouraging corrosion. Temperature swings cause snow to melt into moving parts, then refreeze overnight, locking controls and stressing housings.

Many machines are parked between storms without being dried or inspected. That trapped moisture expands as it freezes, gradually damaging components. Over time, these small issues compound into a failure that shows up at the worst moment.

Common Snow Blower Problems to Look for in January

Snow blower problems after winter storms are most often caused by wet snow, plow berm impacts, and freeze-thaw cycles that strain augers, belts, and control systems. In New Hampshire, these conditions accelerate wear quickly, which is why a post-holiday inspection can reveal damage early and help prevent a mid-season breakdown when storms stack up.

January is the right time for a winter equipment inspection. These are the most common snow blower damage signs that appear after repeated storms.

Auger and Housing Damage

Inspect the auger blades for bending, uneven spacing, or fresh impact marks. Bent augers reduce throwing distance and increase vibration. Look inside the housing for ice buildup or dents that restrict snow flow.

Pay close attention to the scraper bar and skid shoes. Excessive or uneven wear forces the auger to work harder and reduces clearing efficiency. Sudden drops in performance often point to these wear areas.

If you’re unsure what symptoms point to auger or housing issues, Seacoast Power Equipment’s breakdown of common winter snow blower performance problems helps identify likely causes without guesswork.

Belt Wear and Shear Pin Failure

Belts and shear pins absorb much of the strain during heavy snow removal. Check belts for glazing, cracking, or slack. Slipping belts reduce auger engagement and can overheat quickly under load.

Inspect all shear pins. Missing or broken pins indicate the auger struck something solid, often hidden under packed snow. Replace only with the correct OEM-style shear pins. Improvised hardware can lead to serious auger or gearbox damage.

Many of these warning signs match the same indicators outlined in Seacoast Power Equipment’s snow blower service checklist used before winter starts, which applies just as well mid-season.

Chute and Control Freezing Issues

Chute rotation systems and deflectors often freeze after storms. Test chute movement through its full range. Binding or slipping usually means ice buildup, cable corrosion, or worn gears.

Controls should move smoothly without force. Forcing frozen controls frequently leads to broken cables or stripped components. Seacoast Power Equipment’s guidance on safe snow blower operation during winter storms reinforces why proper control function matters for both safety and performance.

Cold Weather Starting Problems

Hard starts, rough idle, or stalling often point to cold-weather fuel or ignition issues. Moisture contamination is common in coastal New Hampshire, especially after machines sit between storms.

If starting reliability has changed, Seacoast Power Equipment’s overview of cold-weather engine problems that cause hard starts explains why fuel condition, oil viscosity, and battery health matter during winter.

When a Winter Equipment Inspection Makes Sense

Professional service is a smart move if you notice:

- New vibration, grinding, or burning smells

- Reduced throwing distance despite a clear housing

- Controls that bind or refuse to stay adjusted

- Repeated shear pin failures

- Oil leaks or fuel odors

A mid-season inspection helps prevent emergency repairs during peak storm demand. If timing is a concern, Seacoast Power Equipment outlines what winter repair turnaround typically looks like, helping set realistic expectations before the next snowfall.

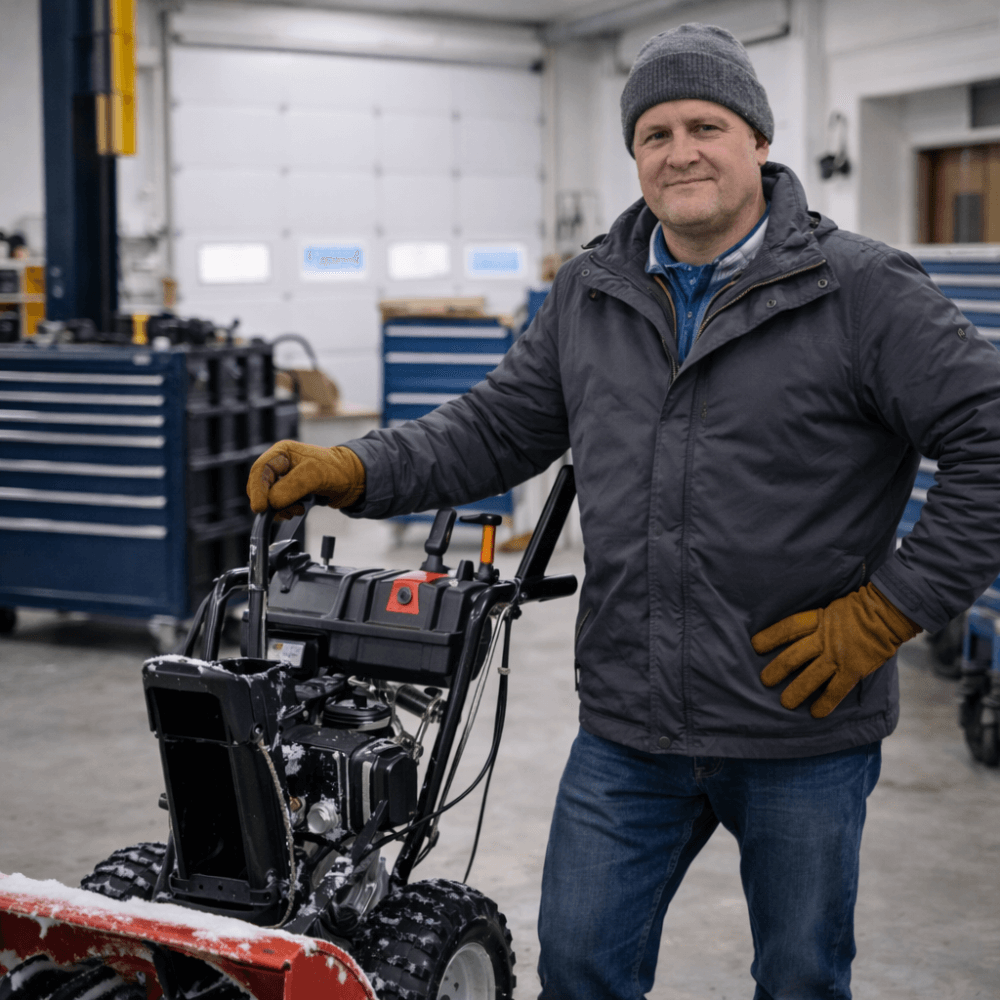

For homeowners who need support beyond basic inspection, Seacoast Power Equipment provides dedicated snow blower repair services in New Hampshire, along with pickup and delivery options when transporting equipment isn’t practical.

How Preventive Maintenance Saves Money Mid-Season

Addressing wear early almost always costs less than fixing a breakdown during a storm. Replacing a worn belt or correcting a control issue now can prevent damage to more expensive components later.

Routine post-storm cleanup also helps. Clearing slush, drying controls, and checking wear points takes only minutes and often reveals problems before they escalate.

Preventive service keeps equipment ready when storms stack up. Scheduling maintenance during calmer weather reduces downtime and avoids the seasonal rush for emergency repairs.

Schedule Snow Blower Service Before the Next Winter Storm Hits

Snow blower problems after winter storms don’t appear out of nowhere. They develop over time, especially under New Hampshire’s harsh winter conditions. A post-holiday inspection can protect your equipment, improve reliability, and prevent costly mid-season failures.

If your snow blower isn’t performing like it did earlier this winter, contact Seacoast Power Equipment. Schedule a winter equipment inspection, request snow blower repair, or arrange pickup and delivery to keep your equipment ready for the next storm.

Seacoast Power helps homeowners and property managers across New Hampshire resolve one of winter’s most common headaches: snow blowers that won’t start. Whether the issue is stale fuel, carburetor trouble, ignition problems, or cold-weather wear and tear, Seacoast Power’s experienced technicians quickly diagnose and repair snow blower starting issues to get equipment back up and running fast. Service is available throughout Barrington, Brentwood, Dover, Durham, Epping, Exeter, Greenland, Hampton, Hampton Falls, Kensington, Kingston, Lee, East Kingston, Madbury, New Castle, Newfields, Newington, North Hampton, Nottingham, Portsmouth, Rye, Rollinsford, Seabrook, Somersworth, and Stratham, with convenient pickup and delivery available in all locations, so customers can get reliable snow removal without the hassle of transporting equipment themselves.

Snow keeps coming. Preparation makes the difference.